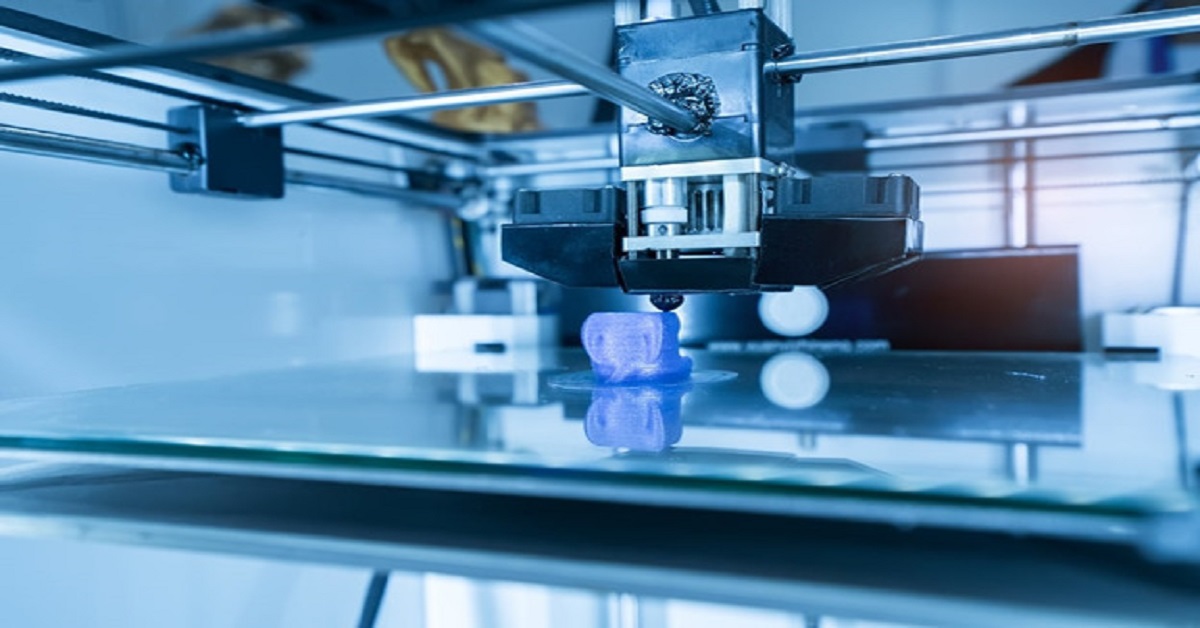

3D Printing is a process that can be used to create three-dimensional objects. It builds up a physical object layer by layer by fusing successive thin layers of material, usually plastic, with heat and pressure. 3D Printing differs from other additive processes in that an entire 3D model is created rather than being drawn manually on paper. The process results in a solid form that can be manipulated at the molecular level simply by adding or removing material in certain areas.

What is 3D Printing?

3D Printing is the process of creating a three-dimensional object from a digital file. It is often used to create prototypes, products, and models.

How does 3D printing work?

First, you create a digital file of the object you want to create. This file contains all the information necessary to create the object.

Next, you use a 3D printer to print the file. The 3D printer uses light and plastic to print the object.

What are the benefits of using 3D Printing?

3D Printing is a fast and cost-effective way to create products. It is also environmentally friendly because it does not use any traditional materials.

3D Printing Processes

3D Printing is a process that uses digital files to create objects from a three-dimensional model. 3D Printing is often used to create prototypes, product parts, and custom designs.

There are several different types of 3D printing processes. Each process has its advantages and disadvantages. The most common 3D printing processes are additive manufacturing (AM), subtractive manufacturing (SD), and fused deposition modeling (FDM).

Additive manufacturing is the most common type of 3D printing process. In this process, objects are created by adding layers of material to a print bed. AM printers use various materials, including plastic, metal, and composites.

Subtractive manufacturing is the second most common type of 3D printing process. In this process, objects are created by removing material from a print bed. SD printers use a variety of materials, including metals and semi-hardwoods.

Fused deposition modeling is the least common type of 3D printing process. In this process, objects are created by depositing layers of material on top of each other. FDM printers use a variety of filaments, including PLA, ABS, and Nylon.

How Long Does 3D Printing Take?

3D Printing is a technology that allows you to create three-dimensional objects from digital models. The process of 3D Printing can take various lengths of time, depending on the type of 3D printing process being used.

There are two main types of 3D printing processes: additive and subtractive. Additive 3D printing uses layers of material to create the object, while subtractive 3D Printing uses a series of cuts to remove material from the object.

The time it takes for 3D Printing depends on various factors, including the size and complexity of the object being printed, the type of printer being used, and the amount of data needed to generate the model.

3D Printing can create a wide range of objects, including products for consumer use, medical devices, and toys. As technology advances, more complex objects will likely be printed using 3D Printing.

Why does 3D Printing Matter?

3D Printing is a process that uses digital files to create a three-dimensional object from a model. This process is used to create difficult or impossible objects to produce using other methods, such as traditional manufacturing.

There are many benefits to using 3D printing technology. One of the most important benefits is that it can enable manufacturers to produce custom products. This is especially important in the field of medical devices and prosthetics.

3D Printing also has applications in the automotive industry, which can be used to create parts for cars and trucks. Finally, 3D Printing is used to create home items, such as furniture and appliances.

The technology behind 3D Printing is constantly evolving, so there are always new applications for this technology. If you are interested in learning more about 3D printing processes, visit our website!

Who Uses 3D Printing Processes?

3D Printing is a process that uses plastic, metal, or other materials to create three-dimensional objects from a digital model.

3D Printing is used in various industries, including the medical and engineering worlds. It is also used to create custom products for consumers.

The three main types of 3D Printing are additive (aka FDM), subtractive (aka CNC), and stereolithography. Each type has its advantages and disadvantages.

Additive 3D printing uses a material layer to build an object from the bottom up. This type of 3D Printing is most commonly used to create objects in plastic or metal.

Subtractive 3D Printing uses a tool to remove material from an object. This type of 3D Printing is best suited for creating complex objects requiring multiple material layers.

Stereolithography is the oldest type of 3D printing technology. It uses light to print objects layer by layer on a substrate. This process is best suited for creating small, simple objects.

Advantages and Disadvantages of using a 3D Printer

3D Printing is a technology that allows you to create three-dimensional objects from digital models. 3D Printing is often used to create manufacturing prototypes, products, and parts.

There are many different types of 3D printers available on the market today. Each has its advantages and disadvantages.

The most common type of 3D printer is the desktop 3D printer. Desktop 3D printers are small and easy to use and can print high-quality objects. However, desktop 3D printers are also expensive, and they require you to have a computer that is capable of running the software required for Printing.

The second most common type of 3D printer is the industrial 3D printer. Industrial 3D printers are larger than desktop 3D printers and can print objects using multiple colours. They also have more features than desktop 3D printers, such as Printing in metal and plastic.

The last type of 3D printer is the mobile 3D printer. Mobile 3D printers are small and lightweight and can be carried around easily. They can also print high-quality objects but are not as durable as industrial or desktop 3D printers.

When to use a 3D Printer

3D Printing is a process that can create objects from digital files. It is a type of manufacturing that uses a 3D printer to create three-dimensional objects from digital models.

3D Printing is used in various industries, including medical technology, aerospace engineering, and product design.

There are two main types of 3D Printing: selective laser sintering (SLS) and stereolithography (SLA). SLS is faster and cheaper than SLA, but SLA can produce higher-quality prints.

3D Printing is growing rapidly due to its many benefits. It has the potential to revolutionize manufacturing, and it can help to reduce costs and environmental impact.